English

Nano Coated Diamond Wire Drawing Dies

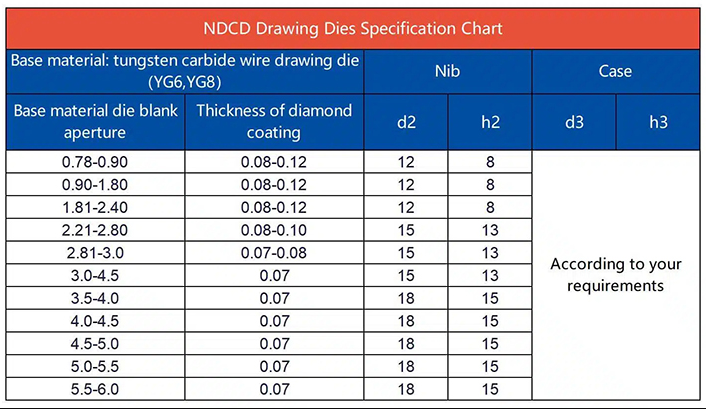

The nano-diamond coating drawing die is made of cemented carbide (WC-Co) as the substrate, and the surface of the inner hole is coated with a micro-nano-scale diamond composite coating by chemical vapour deposition (CVD), which is ground and polished.

Product Description

Wire Drawing Dies

The Advantages of Nano-coated drawing die.

1. Targeted pre-treatment process: make the coating and substrate closely combined.

2. The bottom micron diamond coating has excellent wear resistance.

3. The surface nano diamond coating provides an excellent surface finish and low friction coefficient.

4. Computer simulation and optimization of hole design: high dimensional accuracy, uniform stress on the wire rod, saving raw materials.

5. There is no change in the diameter of the die from use to scrap, reducing the times of downtime inspection and drawing die change and improving production efficiency.

6. Wider diameter range, service life is 5 to 10 times that of tungsten carbide.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine slovenský

slovenský Lietuvos

Lietuvos